Breakfast cereal manufacturing was one of the earliest commercial applications of extrusion cooking technology and remains one of the most widespread.

Extrusion technology was first applied to food materials in the mid 1800s, when chopped meat was stuffed into casing using a piston type extruder. In the 1930s, a single extruder as introduce to the pasta industry.

It is a continuous process by which food biopolymers and ingredients are mixed, plasticized, cooked, and formed by combination of moisture, temperature, pressure, and mechanical shear.

Extrusion cooking is very efficient technology used in the processing grains particularly in processing of breakfast cereals.

It is predominantly a thermomechanical processing operation that combines several unit operations, including mixing, kneading, shearing, conveying, heating, cooling, forming, partial drying, or puffing, depending on the material and equipment used.

During extrusion cooking, the processed materials undergo significant physical and chemical changes. By appropriate selection of process parameters such as temperature, moisture and processing time, the mass becomes entirely gelatinized and cooked.

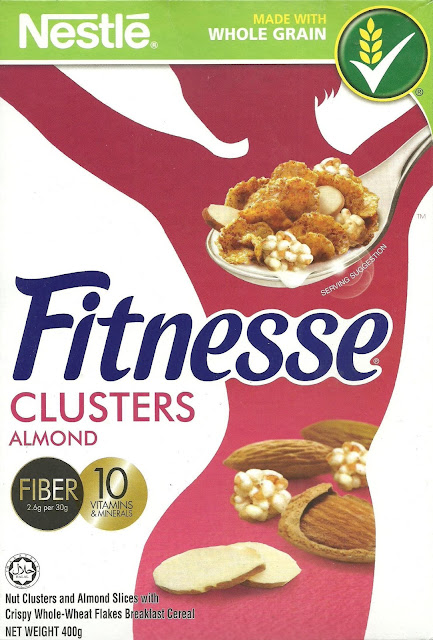

Extrusion cooking is popular for ready to eat cereals, where which they are shaped, toasted, flavored, colored and sometimes enriched or fortified before being packaged and shipped to the consumer.

Just another blog about food processing and the important of food processing. It is about the conversion of raw materials or ingredients into the consumer product. Food processing also can be defined as the branch of manufacturing that starts with raw animal, vegetable, or marine materials and transforms them into intermediate foods stuff or edible products through the application of labor, machinery, energy, and scientific knowledge.

Wednesday, September 26, 2012

Most Popular Articles

-

Direct exchangers are based on mixing of heating steam with the liquid food product resulting in very fast heat transfer rate. Steam injecti...

-

An important crop in Italy and some other Mediterranean countries, the lemon is also grown commercially in the United States. The characteri...

-

Brie, a cheese that is surface ripened by mold, is very similar to Camembert. Differences exist, however, in the internal ripening and in th...

-

Panning is an artisan chocolate-making method that requires slowly pouring chocolate over a round tumbling pan full of nuts, fruits, or any ...

-

Expeller cocoa bitter is the fat prepared by the expeller process from cocoa beans singly or in combination with cocoa nib, cocoa mass, coco...