Various production and processing factors can effect the flavor in addition to the complexity of flavor.

Apart from product safety, flavor stability are important issues for the evaluation by the consumer.

Therefore the requirements for the flavor of the final product are increasing. This requires extensive knowledge in various field:

*Processing properties of the flavor

*Behavior of the flavor during the production of the food

*Behavior of the flavor during the shelf life of the food

*Interactions of flavor and foodstuff.

Minor effects from processing include those from filtration, aeration and freezing, but by far the most important factor is heat.

This may cause chemical changes in the flavor, but the main problem is the loss of volatiles.

This may have the effect of reducing the fresh top note of a flavor. If the key recognition chemicals have widely different boiling points, heat could render the flavor unrecognizable.

The products odor, as well as its taste, contribute to its flavor. The favor industry works very closely in many areas to recover volatiles lost in processing which when treated from valuable entities.

The choice of solvent can reduce this problem. In some instances, volatile chemicals may be replaced by higher boiling analogues.

In processes involving considerable heat, such as bakery and extrusion, the best solution is multiple encapsulation.

Numerous new volatile compounds are formed during the processing of grain. Although they are often identical compounds, their amounts and relative proportions may vary significantly depending on the process parameters, thereby resulting in different flavors.

Important flavor compounds in rye sourdough are alcohols, ester and carbonyls. In baking, mainly compounds related to the Millard reaction form: alcohols, acids, aldehydes, hydrocarbon-substitutes furans, ketones, lactones, pyrazines, hydrocarbon-substituted pyroles, and sulphur compounds.

Processing Factors on Flavor

Just another blog about food processing and the important of food processing. It is about the conversion of raw materials or ingredients into the consumer product. Food processing also can be defined as the branch of manufacturing that starts with raw animal, vegetable, or marine materials and transforms them into intermediate foods stuff or edible products through the application of labor, machinery, energy, and scientific knowledge.

Showing posts with label factor. Show all posts

Showing posts with label factor. Show all posts

Thursday, August 18, 2011

Sunday, July 19, 2009

Food Spoilage and Physical Factors

Food spoilage can also be caused by physical factors, such as temperature, moisture and pressure acting upon the foods.

Moisture and heat can also produce hydrolytic rancidity in fats; in this case, fats are split into free fatty acids, which may cause off odors and rancid flavors in fats and oils.

Excessive heat denatures proteins, breaks emulsions, removes moisture from food and destroys nutrients such as vitamins.

However, excessive coldness, such as freezing, also discolors fruits and vegetable, changes their texture and/or cracks their outer coatings to permit contamination by organisms.

Food under pressure will be squeezed and transformed into unnatural conformation. The compression will likely break up the surface structure, release degradative enzymes, and expose the damage food to exterior microbial contamination.

Many health officials consider physical factors to include such things as sand, glass, wood chips, rat hair, animal urine, bird droppings, insect parts and so on. These things may not spoil the food, but they do present hazards.

Some these foreign substances do lead to spoilage.

Furthermore, insects and rodents can consume and damage stores foods and insect can lay eggs and leave larvae in the foods, causing further damage later.

Such foods are no longer reliable since they contain hidden contaminants.

The attacks of the by insect and rodents can also contaminate foods further with microbial infections.

Tuesday, January 02, 2007

The Effect of drying on microorganisms

The Effect of drying on microorganisms

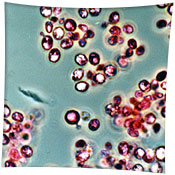

The main purpose of drying foods is to lower their moisture content to a particular level that will exclude the growth of microorganisms (bacteria, mould and yeasts).

For any given moisture content, one food may support the growth of microorganisms will growth in a dried food depends on the water activity.

The lower the water activity of a food, the less probable that microorganisms will grow. Generally, mold at lower water activities than yeasts and yeasts will grow at lower water activities than bacteria. For this reason, mold are opt to grow in dried foods than are yeasts or bacteria.

In dried foods, the moisture content is lowered to the point which microorganisms will not grow and it is kept that way through packaging, which includes moisture.

Water activity also can be lowered by soluble components, such as sugar or salt.

Thus, certain syrup and salted, partially dried foods (e.g foods) are relatively stable as far as at the growth of microorganisms is concerned , although there may be conditions in which they become subject to the growth of yeasts or molds.

The Effect of drying on microorganisms

Labels:

drying,

factor,

microorganism,

moisture

Subscribe to:

Posts (Atom)

Most Popular Articles

-

Milling is the process of removing the husk and splitting whole lentils to produce edible dal. The effectiveness of this process directly in...

-

Direct heating involves direct contact between the food and the heating medium by steam injection or steam infusion. Steam injection intro...

-

Spray drying instant coffee refer to a type of coffee that has been treated with a spray drying process that remove all the water from the c...

-

One of the functions of food additives is to maintain product consistency and also improve mouth-feel. Such as emulsifiers give products a...

-

Yes, alcohol can indeed be made from dates using a traditional process known in some cultures as Dakhai. This method utilizes the natural s...