There are four main methods used to process coffee: Washed Process, Natural (or Dry) Process, Wet hulled and Honey Process.

Dry process is a method of processing coffee beans to remove the fruit of the cherry and dry the bean. In the dry method, the usual objective is to harvest all cherries simultaneously with the least percentage of unripe ones.

The ideal situation is to harvest all fresh, ripe cherries with the least possible damage to the tree, irrespective of the processing system to be used. The cherries are picked ripe, which is important since the fruit itself imparts flavor during this process. They are sorted and weighed before moving to the drying area.

In this method, the coffee cherries are laid out in the sun on a concrete drying patio, or raised beds. Raised beds are preferred because they increase the airflow around the whole fruit to enable more even drying. The coffee is shifted every 30-40 minutes.

Throughout the course of 3-6 weeks, the coffees will ferment, as producers rake these cherries and rotate them to prevent spoiling. During this time, the sugars and mucilage (that sticky substance that coats the seed) will latch onto the seeds, which develop flavors and make them sweeter.

Raking also prevents bruising on the fruit where it’s in contact with the patio or tarp on which it’s resting. Producers are vigilant about avoiding bruising because it can cause flavor defects.

Coffee must be dried from approximately 60% moisture content to 11-12% moisture content. After a period of 3 - 6 weeks, the husk of the dried cherry is removed mechanically. The resulting coffee is often referred to as unwashed. This is the oldest method of processing coffee and is more ecologically friendly, as it does not require water.

Natural sundried, also called “natural process” or “dry process,” means drying coffee cherries whole without the intervention of water or machines to remove any of the fruit. Drying should be uniform to obtain acceptable color, size along with the removal of pests for a longer safe storage. Since coffee production is seasonal, traditional sun drying is quite tough.

This method is widely used in Brazil, but less widely used in Guatemala or Costa Rica where the coffee is more often piled perpendicularly to the old piles.

Dry or natural method processing of coffee

Just another blog about food processing and the important of food processing. It is about the conversion of raw materials or ingredients into the consumer product. Food processing also can be defined as the branch of manufacturing that starts with raw animal, vegetable, or marine materials and transforms them into intermediate foods stuff or edible products through the application of labor, machinery, energy, and scientific knowledge.

Showing posts with label drying. Show all posts

Showing posts with label drying. Show all posts

Sunday, May 14, 2023

Sunday, September 29, 2019

Food Processing: Hot air drying

Drying may be defined as the vaporization and removal of water or other liquids from a solution, suspension, or other solid-liquid mixture to form a dry solid. It is a complicated process that involves simultaneous heat and mass transfer, accompanied by physicochemical transformations.

During the drying process, two types of resistance control water transport: internal resistance to the water movement inside the material and external resistance between the solid surface and the air. Internal resistance is a characteristic of the material, while external resistance depends on the thickness of the diffusion boundary layer.

Among drying medium, hot air is the commonest, in spite of superheated steamhas shown higher efficiency and higher product quality in some special cases. For removing moisture and preserving the food, drying technique is one of the earliest techniques. By means of this way, the shelf-life of a product can be prolonged significantly. Drying technique also influences other characteristics, such as palatability of food, flavor, aroma, viscosity, hardness, microbial spoilage and enzymatic activity.

For drying fruits and vegetables, hot air drying is the most common one, which is both the simplest and most economical technology. In this technique, the need for elevated temperatures or lengthy drying durations may provoke severe harm to flavor, color, and nutrients of the product and it may also reduce rehydration capacity and bulk density of the dried fruit.

Food Processing: Hot air drying

During the drying process, two types of resistance control water transport: internal resistance to the water movement inside the material and external resistance between the solid surface and the air. Internal resistance is a characteristic of the material, while external resistance depends on the thickness of the diffusion boundary layer.

Among drying medium, hot air is the commonest, in spite of superheated steamhas shown higher efficiency and higher product quality in some special cases. For removing moisture and preserving the food, drying technique is one of the earliest techniques. By means of this way, the shelf-life of a product can be prolonged significantly. Drying technique also influences other characteristics, such as palatability of food, flavor, aroma, viscosity, hardness, microbial spoilage and enzymatic activity.

For drying fruits and vegetables, hot air drying is the most common one, which is both the simplest and most economical technology. In this technique, the need for elevated temperatures or lengthy drying durations may provoke severe harm to flavor, color, and nutrients of the product and it may also reduce rehydration capacity and bulk density of the dried fruit.

Food Processing: Hot air drying

Sunday, June 30, 2019

Hot air drying

The term drying refers generally to the removal of moisture from a

substance. It is one of the oldest, most commonly used and most energy

consuming unit operation in the process industries.

The hot air drying technique is the most frequently used technique to produce dehydrated vegetables and fruits, in which heat is transferred from the hot air to the product by convection, and evaporated water is transported to the air also by convection.

Air that has a low moisture concentration is blown through the material bed so that it absorbs water molecules from the product away. In some dryers the air flow is also what is used to heat the material being dried.

Hot air driers are classified as parallel flow, counter flow, direct flow, or cross flow, pending on the direction in the product moves in direction to the direction of flow of the heated air.

Hot-air drying is efficient at removing free water as long as it’s present as continuous liquid phase (high water content) preventing thermal deterioration of the products; this removal is governed by Fick’s Law. The water elimination generates shrinkage decreasing the internal water diffusivity and increasing the thermal conductivity of the product and thus the internal heat transfer.

Hot air drying

The hot air drying technique is the most frequently used technique to produce dehydrated vegetables and fruits, in which heat is transferred from the hot air to the product by convection, and evaporated water is transported to the air also by convection.

Air that has a low moisture concentration is blown through the material bed so that it absorbs water molecules from the product away. In some dryers the air flow is also what is used to heat the material being dried.

Hot air driers are classified as parallel flow, counter flow, direct flow, or cross flow, pending on the direction in the product moves in direction to the direction of flow of the heated air.

Hot-air drying is efficient at removing free water as long as it’s present as continuous liquid phase (high water content) preventing thermal deterioration of the products; this removal is governed by Fick’s Law. The water elimination generates shrinkage decreasing the internal water diffusivity and increasing the thermal conductivity of the product and thus the internal heat transfer.

Hot air drying

Labels:

drying,

hot air drying,

moisture

Saturday, April 27, 2019

Mechanical drying of raisins

Grapes intended for dehydration are hand harvested and transported to

the drying facility in pallet bins. In artificial drying, grapes are

first dipped n 0.25 – 1 % lye (sodium hydroxide) solution at 200 – 212

degree F for 2 – 5 sec to remove a natural wax that impedes drying and

to produce tiny cracks in the skin of the fruit in order to speed

drying.

The fruit is then placed on trays and exposed to gaseous sulfur dioxide. This is to prevent enzymatic and nonenzymatic browning during drying. Hence instead of having the dark brown color of raisins that normally be expected, the raisins will be of a light yellow color when dried. The purpose of the pretreatment is to increase the permeability of the grape skin to moisture.

There are three main methods that are used for fruit drying: sun drying, shade drying and mechanical drying. Mechanical drying which is safe, rapid, and controllable is attractive to dry fruit production, especially when high throughput is needed.

Raisins are dried at temperatures not exceeding 165 degree F and at a low relative humidity. After the moisture content has been lowered to about 16 – 18%, the raisins are packaged in containers of various sizes to be sold at retail or for use by the food industry.

Mechanical drying of raisins

The fruit is then placed on trays and exposed to gaseous sulfur dioxide. This is to prevent enzymatic and nonenzymatic browning during drying. Hence instead of having the dark brown color of raisins that normally be expected, the raisins will be of a light yellow color when dried. The purpose of the pretreatment is to increase the permeability of the grape skin to moisture.

There are three main methods that are used for fruit drying: sun drying, shade drying and mechanical drying. Mechanical drying which is safe, rapid, and controllable is attractive to dry fruit production, especially when high throughput is needed.

Raisins are dried at temperatures not exceeding 165 degree F and at a low relative humidity. After the moisture content has been lowered to about 16 – 18%, the raisins are packaged in containers of various sizes to be sold at retail or for use by the food industry.

Mechanical drying of raisins

Labels:

drying,

pre-treatment,

temperature

Wednesday, December 05, 2018

Manufacturing process of raisins

Raisins are the second most important product of the grapevine wine,

being the first. The quality of raisins depends on the size of the

raisins berries, the uniformity and brilliance of the berry color, the

condition of the berry surface, the texture of the skin and pulp in the

berry, moisture content, chemical position and presence of decay, mold,

yeast and foreign matter.

Raisins are produced from grapes by sun during and artificial drying. In the traditional drying method, grape bunches are spread over either the ground or on a platform or on wooden trays in a thin layer between the rows of grapes vines.

The trays are tilted to face the sun. After they are partially dried, the grape bunches are turned and allowed to dry to the point where no juice can be pressed out. The trays are then stacked, and the air drying is continued in the shade until moisture content of about 17% reached. After drying, the raisins are placed in sweat boxes to equilibrate, or to even out, the moisture that is present, and then they are packed in retail size containers or in larger containers to be sold to the bakery trade.

This method of drying is most cost-effective and takes approximately 8-10 days to produce dried products.

In artificial drying, grapes are first dipped in 0.25 – 1 % lye (sodium

hydroxide) solution at 200 – 212 degree F for 2 – 5 sec to remove a

natural wax that impedes drying and to check or crack the skin of the

grape to facilitate drying

They are then washed, placed on trays, and treated with sulfur dioxide to prevent enzymatic and nonenzymatic browning during drying. Hence instead of having the dark brown color of raisins that normally be expected, the raisins will be of a light yellow color when dried.

Raisins are dried at temperatures not exceeding 165 degree F and at a low relative humidity. After the moisture content has been lowered to about 16 – 18%, the raisins are packaged in containers of various sizes to be sold at retail or for use by the food industry.

In California, light-colored raisins are produced mostly by the golden bleach process. First, Thompson Seedless grapes are sorted, then they are dipped to produce slight checking cracking of the skins, and they are cooled and washed in a spray of cold water. They are exposed to the fumes of burning sulfur in a sulfur house. After being sulfured, the grapes are dehydrated at a temperature of 140 to 160 degree F.

Manufacturing process of raisins

Raisins are produced from grapes by sun during and artificial drying. In the traditional drying method, grape bunches are spread over either the ground or on a platform or on wooden trays in a thin layer between the rows of grapes vines.

The trays are tilted to face the sun. After they are partially dried, the grape bunches are turned and allowed to dry to the point where no juice can be pressed out. The trays are then stacked, and the air drying is continued in the shade until moisture content of about 17% reached. After drying, the raisins are placed in sweat boxes to equilibrate, or to even out, the moisture that is present, and then they are packed in retail size containers or in larger containers to be sold to the bakery trade.

This method of drying is most cost-effective and takes approximately 8-10 days to produce dried products.

They are then washed, placed on trays, and treated with sulfur dioxide to prevent enzymatic and nonenzymatic browning during drying. Hence instead of having the dark brown color of raisins that normally be expected, the raisins will be of a light yellow color when dried.

Raisins are dried at temperatures not exceeding 165 degree F and at a low relative humidity. After the moisture content has been lowered to about 16 – 18%, the raisins are packaged in containers of various sizes to be sold at retail or for use by the food industry.

In California, light-colored raisins are produced mostly by the golden bleach process. First, Thompson Seedless grapes are sorted, then they are dipped to produce slight checking cracking of the skins, and they are cooled and washed in a spray of cold water. They are exposed to the fumes of burning sulfur in a sulfur house. After being sulfured, the grapes are dehydrated at a temperature of 140 to 160 degree F.

Manufacturing process of raisins

Labels:

drying,

grapes,

manufacturing,

raisins

Thursday, March 01, 2018

Hot air drying

Drying is an efficient way to reduce moisture content and water activity for food preservation. Most fruits, vegetable and food materials are dried to different extents in terms of product identification.

Hot air drying is probably the most common method of industrial food drying. It is one such method in which the solid to be dried is exposed to continuously flowing of stream of air where moisture evaporates. When mechanical dehydrators are used, the product is placed on meal mesh belts in a tunnel, or in a cabinet on trays where controlled, elevate temperatures are used.

Heated air circulated by blowers and the air temperature, relative humidity and air velocity are controlled.

Hot air drying employs a heater to raise the temperature and increase the energy content of the drying air. Saturated or superheated steam and electrical heating devices are always the major heat sources.

Hot air drying

Hot air drying is probably the most common method of industrial food drying. It is one such method in which the solid to be dried is exposed to continuously flowing of stream of air where moisture evaporates. When mechanical dehydrators are used, the product is placed on meal mesh belts in a tunnel, or in a cabinet on trays where controlled, elevate temperatures are used.

Heated air circulated by blowers and the air temperature, relative humidity and air velocity are controlled.

Hot air drying employs a heater to raise the temperature and increase the energy content of the drying air. Saturated or superheated steam and electrical heating devices are always the major heat sources.

Hot air drying

Labels:

drying,

hot-air drying

Sunday, December 04, 2016

Post-harvest of pistachio

Harvesting of pistachio is some regions of the world depend on hand labor. But in California, when most of the nuts are ripe and begin splitting, they are mechanically harvested, cleaned and placed in bins for transport to a processing plant.

Pistachios destined for the fresh market are cooled straight after harvest. All sticks, leaves and other debris and reject nuts are removed before they are graded, hand sorted and packed into polystyrene. The nuts should be stored in a cool room at all times.

Pistachios destined for sale as dried nuts are hulled as soon as possible. Freshly harvested nuts have a moisture content of around 45%. After harvest the nuts are cleaned and dried to around 5% using forced-air drying. Natural air drying can be employed in low humidity and high temperature conditions.

Then hull of the pistachio must be removed within 24 hr of harvest to prevent shell staining. Stained pistachio nuts are less attractive to consumers and have higher incidence of aflatoxin contamination.

After drying, electronic sorters cull out blemished nuts. Good quality splits are graded into four sizes. To achieve the most uniform grades, the size graders operate via a combination of round and slotted holes. This followed by roasting, salting and packaging. Around 90% of consumer-packed nuts from California are roasted and salted in the shell.

Pistachio is widely used in the pastry, confectionery and ice-cream industries for its pleasing flavor and green color.

Post-harvest of pistachio

Pistachios destined for the fresh market are cooled straight after harvest. All sticks, leaves and other debris and reject nuts are removed before they are graded, hand sorted and packed into polystyrene. The nuts should be stored in a cool room at all times.

Pistachios destined for sale as dried nuts are hulled as soon as possible. Freshly harvested nuts have a moisture content of around 45%. After harvest the nuts are cleaned and dried to around 5% using forced-air drying. Natural air drying can be employed in low humidity and high temperature conditions.

Then hull of the pistachio must be removed within 24 hr of harvest to prevent shell staining. Stained pistachio nuts are less attractive to consumers and have higher incidence of aflatoxin contamination.

After drying, electronic sorters cull out blemished nuts. Good quality splits are graded into four sizes. To achieve the most uniform grades, the size graders operate via a combination of round and slotted holes. This followed by roasting, salting and packaging. Around 90% of consumer-packed nuts from California are roasted and salted in the shell.

Pistachio is widely used in the pastry, confectionery and ice-cream industries for its pleasing flavor and green color.

Post-harvest of pistachio

Labels:

drying,

grading,

nuts,

pistachio,

post-harvest,

processing

Thursday, October 13, 2016

Drying process of milk using drum dryer

The main drying process of skim milk powder and whole milk powder is spray drying. However, drum drying and fluid-bed drying are used for special purposes.

In drum drying the milk is distributed on rotating, steam-heated drums, where the water evaporates.

Drum dryers were introduced into industries about 100 years ago and it starting with the double-drum dryer which features the feeding by nipping between two drums. J. A Just was one of the first inventors to receive –patent rights on a drum dryer with two rolls in 1902.

Drum dryer consists of one or more hollow metal cylindrical rolls or drums that are mounted to rotate on horizontal axes at a variable speed.

Using film evaporating systems, the milk is first pre-concentrated to 40-50% solids. A thin layer or film of product is dried over an internally steam-heated drum with steam pressure up to 620 kPa and 149 °C. Approximately 1.2 – 1.3 kg steam are required per kilogram of water evaporated.

The film dries as the drum rotates. The dried milk then is scraped from the drum surface, as they rotate, by metal scraper. The feeding materials can be slurries, paste, or solutions and final dried products are in the form of powders, flakes or chips.

The operating variables for a drum dryer include condensation of incoming product in an elevator, temperature of incoming product, steam pressure in drum, speed of drum, and height of product over drum.

In the process, relatively large particles are obtained. It has poor dissolving properties and where sold for domestic use is subjected to further instantisation, which agglomerates granules and leads to a faster dissolution time.

Drying process of milk using drum dryer

In drum drying the milk is distributed on rotating, steam-heated drums, where the water evaporates.

Drum dryers were introduced into industries about 100 years ago and it starting with the double-drum dryer which features the feeding by nipping between two drums. J. A Just was one of the first inventors to receive –patent rights on a drum dryer with two rolls in 1902.

Drum dryer consists of one or more hollow metal cylindrical rolls or drums that are mounted to rotate on horizontal axes at a variable speed.

Using film evaporating systems, the milk is first pre-concentrated to 40-50% solids. A thin layer or film of product is dried over an internally steam-heated drum with steam pressure up to 620 kPa and 149 °C. Approximately 1.2 – 1.3 kg steam are required per kilogram of water evaporated.

The film dries as the drum rotates. The dried milk then is scraped from the drum surface, as they rotate, by metal scraper. The feeding materials can be slurries, paste, or solutions and final dried products are in the form of powders, flakes or chips.

The operating variables for a drum dryer include condensation of incoming product in an elevator, temperature of incoming product, steam pressure in drum, speed of drum, and height of product over drum.

In the process, relatively large particles are obtained. It has poor dissolving properties and where sold for domestic use is subjected to further instantisation, which agglomerates granules and leads to a faster dissolution time.

Drying process of milk using drum dryer

Labels:

drum drying,

drying,

milk,

operation

Monday, April 11, 2016

Milk powder spray drying

Dried milk is manufactured from evaporated milk. In spray drying, the milk concentrate is finely dispersed in the spray tower by centrifugal atomization or by nozzle atomization and dried with hot air (150-220 °C). The final drying process reduces the water content to about 4%.

The removal of water by spray drying is an energy expensive process and even if it were not, spray drying would not normally be chosen as the only methods of water removal in milk powder production.

Spray dried powder consists of small, regular spherical particles, is light in color and had very little burnt taste.

In general, there are four stages in spray drying of drying milk powder, these are:

*Atomization of milk into a spray, at the top of the atomizing chamber

*Spray-air contact, mixing and flow

*Drying of spray droplets in flight

*Collection and separation process of milk powder from the air

Spray dried powder is generally considered to be of better organoleptic quality than roller dried.

Spray dried milk has poor dissolving properties and subjected to a further process, instantisation which agglomerates granules and leads to a faster dissolution time.

Milk powder spray drying

The removal of water by spray drying is an energy expensive process and even if it were not, spray drying would not normally be chosen as the only methods of water removal in milk powder production.

Spray dried powder consists of small, regular spherical particles, is light in color and had very little burnt taste.

In general, there are four stages in spray drying of drying milk powder, these are:

*Atomization of milk into a spray, at the top of the atomizing chamber

*Spray-air contact, mixing and flow

*Drying of spray droplets in flight

*Collection and separation process of milk powder from the air

Spray dried powder is generally considered to be of better organoleptic quality than roller dried.

Spray dried milk has poor dissolving properties and subjected to a further process, instantisation which agglomerates granules and leads to a faster dissolution time.

Milk powder spray drying

Labels:

dry milk,

drying,

milk powder,

spray drying

Friday, March 18, 2016

Tea leaves drying process

Drying achieved by blowing hot air through tea leaves, arrests oxidation by inactivating enzymes, resulting in color enhancement and the final balance of tea aroma and reduces the moisture content of the leaves to less than5%.

In Keemun black tea processing, the leaves are subjected to drying after fermentation at 110 °C– 120 °C for 10 – 15 min. The moisture will drop below 20%.

After spreading the first dried leaves, another drying is carried out at 70 °C – 90°C for 45 –60 min to moisture below 4%.

Drying is usually done by a drying machine such as the multi-band drier or fluid bed drier.

The temperature is sufficient to inactivate the polyphenol oxidases. The sap released during rolling and fermentation solidifies during drying on the fine little hair on the surface of the leaf.

During drying, aroma substances are formed and the coppery-red color is changed to black (hence ‘black tea’).

Following the drying the leaves are sorted and graded to yield a commercial product.

Tea leaves drying process

In Keemun black tea processing, the leaves are subjected to drying after fermentation at 110 °C– 120 °C for 10 – 15 min. The moisture will drop below 20%.

After spreading the first dried leaves, another drying is carried out at 70 °C – 90°C for 45 –60 min to moisture below 4%.

Drying is usually done by a drying machine such as the multi-band drier or fluid bed drier.

The temperature is sufficient to inactivate the polyphenol oxidases. The sap released during rolling and fermentation solidifies during drying on the fine little hair on the surface of the leaf.

During drying, aroma substances are formed and the coppery-red color is changed to black (hence ‘black tea’).

Following the drying the leaves are sorted and graded to yield a commercial product.

Tea leaves drying process

Labels:

drying,

heating,

moisture,

tea leaves

Friday, October 23, 2015

Process of preservation by removal of water

Removal of water and the consequent lowering of water activity constitutes an important principle of food preservations. The removal of water is usually done by drying dehydration, or evaporation.

Although the term are sometimes interchangeably, drying normally refer to the sun drying, or air drying, evaporation refers to drying by the application of artificial heat but under natural draft, and dehydration implies drying by controlling application of application heat with mechanical circulation of air or under a vacuum.

Drying of food involves complete removal of water under controlled conditions in such a way that the food is not altered and results in minimum changes by the drying process. Dried foods contain moisture to the extend of 1-5 per cent and they have storage stability at room temperature of a year or longer.

The term dehydration refers generally to artificial drying under control conditions. However, in modern food processing the term does not refer to all processes that remove water from foods.

Evaporation is the removal by vaporization of part of the solvent form a solution or dispersion of essentially non-volatile solutes. Evaporation is distinguished from crystallization and drying by the fact that the final product is a concentrated dispersion or solution rather than precipitate solids.

Process of preservation by removal of water

Although the term are sometimes interchangeably, drying normally refer to the sun drying, or air drying, evaporation refers to drying by the application of artificial heat but under natural draft, and dehydration implies drying by controlling application of application heat with mechanical circulation of air or under a vacuum.

Drying of food involves complete removal of water under controlled conditions in such a way that the food is not altered and results in minimum changes by the drying process. Dried foods contain moisture to the extend of 1-5 per cent and they have storage stability at room temperature of a year or longer.

The term dehydration refers generally to artificial drying under control conditions. However, in modern food processing the term does not refer to all processes that remove water from foods.

Evaporation is the removal by vaporization of part of the solvent form a solution or dispersion of essentially non-volatile solutes. Evaporation is distinguished from crystallization and drying by the fact that the final product is a concentrated dispersion or solution rather than precipitate solids.

Process of preservation by removal of water

Labels:

dehydration,

drying,

evaporation,

method,

preservation

Wednesday, February 11, 2015

Drum dryer operation

The drum dryer is a continuous contact dryer widely used in the food industry for drying products initially in liquid form.

It is highly flexible equipment consists of one or two horizontally mounted hollow cylinders made of high-grade casts iron or stainless steel, a supporting, a product feeding system, a scrapper and auxiliaries.

The variety of feed arrangements available ensures that solution, suspension and pastes with a wide range of viscosities can be dried.

In drum drying, a thick film of feedstock is applied to the external surface of a heated drum which rotates slowly about its horizontal axis.

The feed can be pre-concentrated and preheated to reduce the drying load but there is a limit to the feed concentration beyond which the sheet may not form well.

In operation steam at temperature up to 200 °C heats the inner surface do the drum. The moist material is uniformly applied in a thin layer (0.5 - 2mm) onto the outer drum surface.

The layer of material remains attached to the drum for about 80% of a revolution drum which time moisture evaporates and leaves behind a layer of solids, which is subsequently removed from the drum surface by a scrapper or doctor knife.

There are many types of drum dryer available:

*Atmospheric double drum dryers

*Atmospheric single drum dryers

*Atmospheric twin drum dryers

*Enclosed drum dryers

*Vacuum Double drum dryers

The single-drum comprises only one roll. A double drum dryer comprises two rolls, which rotate toward each other at the top.

By using the drum dryer, the products have a good porosity and hence good rehydration due to boiling evaporation.

Drum dryers also can dry viscous foods, such as pastes and gelatinized or cooked starch, which cannot be easily dried with other methods.

Drum dryer operation

It is highly flexible equipment consists of one or two horizontally mounted hollow cylinders made of high-grade casts iron or stainless steel, a supporting, a product feeding system, a scrapper and auxiliaries.

The variety of feed arrangements available ensures that solution, suspension and pastes with a wide range of viscosities can be dried.

In drum drying, a thick film of feedstock is applied to the external surface of a heated drum which rotates slowly about its horizontal axis.

The feed can be pre-concentrated and preheated to reduce the drying load but there is a limit to the feed concentration beyond which the sheet may not form well.

In operation steam at temperature up to 200 °C heats the inner surface do the drum. The moist material is uniformly applied in a thin layer (0.5 - 2mm) onto the outer drum surface.

The layer of material remains attached to the drum for about 80% of a revolution drum which time moisture evaporates and leaves behind a layer of solids, which is subsequently removed from the drum surface by a scrapper or doctor knife.

There are many types of drum dryer available:

*Atmospheric double drum dryers

*Atmospheric single drum dryers

*Atmospheric twin drum dryers

*Enclosed drum dryers

*Vacuum Double drum dryers

The single-drum comprises only one roll. A double drum dryer comprises two rolls, which rotate toward each other at the top.

By using the drum dryer, the products have a good porosity and hence good rehydration due to boiling evaporation.

Drum dryers also can dry viscous foods, such as pastes and gelatinized or cooked starch, which cannot be easily dried with other methods.

Drum dryer operation

Labels:

drum dryer,

drying,

heating,

process

Tuesday, February 11, 2014

Manufacturing of banana powder

Banana puree is the first step in banana powder processing. Good quality puree with proper drying produces good quality powder.

Banana powder is made from fully ripe banana pulp. Passage through a colloidal mill converts the pulp into a fine paste.

A 1 or 2% sodium metabisulfite solution is added at this stage to improve the color of the final product or to prevent discoloration.

Both spray and drum drying may be used; however, the latter is more favorable as it allows the recovery of all solids.

In the drum dried method, the moisture content of the pulp is reduced to 8 – 12% and then it is further decreased to 2% by drying at 60 ° C in a tunnel or cabinet dryer.

A typical spray drier can produce 70 kg of powder per hour, giving yields of 8 – 11% of the fresh fruit, but drum drying gives a final yield of about 13% of the fresh fruit.

Banana powder with spray drying

Banana powder is prepared by spray drying of fully ripe banana pulp after adding milk solids at a 10% level.

Spray drying of food rich in invert sugar is difficult because of their thermoplastic nature, which results in the adherence of the dried matter to the sides of the sprayer and necessities scrubbing.

However, when milk solids are added, spraying becomes easy and the material does not stick to the walls of the sprayer.

The dry powder is highly hygroscopic and is packed in bag-in-box packages. The bags are made from laminated material with moisture barrier layers.

Manufacturing of banana powder

Banana powder is made from fully ripe banana pulp. Passage through a colloidal mill converts the pulp into a fine paste.

A 1 or 2% sodium metabisulfite solution is added at this stage to improve the color of the final product or to prevent discoloration.

Both spray and drum drying may be used; however, the latter is more favorable as it allows the recovery of all solids.

In the drum dried method, the moisture content of the pulp is reduced to 8 – 12% and then it is further decreased to 2% by drying at 60 ° C in a tunnel or cabinet dryer.

A typical spray drier can produce 70 kg of powder per hour, giving yields of 8 – 11% of the fresh fruit, but drum drying gives a final yield of about 13% of the fresh fruit.

Banana powder with spray drying

Banana powder is prepared by spray drying of fully ripe banana pulp after adding milk solids at a 10% level.

Spray drying of food rich in invert sugar is difficult because of their thermoplastic nature, which results in the adherence of the dried matter to the sides of the sprayer and necessities scrubbing.

However, when milk solids are added, spraying becomes easy and the material does not stick to the walls of the sprayer.

The dry powder is highly hygroscopic and is packed in bag-in-box packages. The bags are made from laminated material with moisture barrier layers.

Manufacturing of banana powder

Tuesday, October 28, 2008

Pretreatment before Process of Drying

Pretreatment before Process of Drying

The preservation of foods by drying is probably the oldest food preservation process practiced by humans. It is believed that many foods, especially grains and fruits of high sugar content, were preserved by primitive peoples by allowing them to dry in the sun. Spices and fish, cut into thin strips, were also preserved in this manner.

There are number of different methods of drying foods for preservation. The most important are sun drying, tunnel or cabinet drying, drum drying, spray drying and freeze drying.

There are number of different methods of drying foods for preservation. The most important are sun drying, tunnel or cabinet drying, drum drying, spray drying and freeze drying.

Foods to be dried must be washed, and some peeled and cut. Others may be pre cooked. Cut fruits are subjected to darkening through enzymes action and must be either blanched or treated with salts or sulfur dioxide. However if treated with sulfur dioxide, the product must be so labeled, because of known allergenic reactions in some consumers. Certain vegetables may be pretreated in the same manner. Sulfuring may also be required to limit non enzymatic browning (the Maillard reactions). Browning refers to the development of brown color.

Various dried eggs products are also subject to browning and also susceptible to the development of off flavors. In this case, the reaction involves a combination of small amount of glucose, which is naturally present, with proteins. Because of this, dried eggs products, especially egg whites, may be treated with glucose oxidase and catalase. The glucose oxidase converts glucose to gluconic acid (which does not combine with amino groups) and hydrogen peroxide. The purpose of the catalase is to convert the undesirable peroxide to water and oxygen. The elimination of glucose may also be done by natural fermentation using microbes. However this process can be considered unsanitary and in order to avoid product spoilage and even food poisoning, it is necessary to hold the product at 130 degree F for several hours after drying.

Various dried eggs products are also subject to browning and also susceptible to the development of off flavors. In this case, the reaction involves a combination of small amount of glucose, which is naturally present, with proteins. Because of this, dried eggs products, especially egg whites, may be treated with glucose oxidase and catalase. The glucose oxidase converts glucose to gluconic acid (which does not combine with amino groups) and hydrogen peroxide. The purpose of the catalase is to convert the undesirable peroxide to water and oxygen. The elimination of glucose may also be done by natural fermentation using microbes. However this process can be considered unsanitary and in order to avoid product spoilage and even food poisoning, it is necessary to hold the product at 130 degree F for several hours after drying.

Pretreatment before Process of Drying

The preservation of foods by drying is probably the oldest food preservation process practiced by humans. It is believed that many foods, especially grains and fruits of high sugar content, were preserved by primitive peoples by allowing them to dry in the sun. Spices and fish, cut into thin strips, were also preserved in this manner.

There are number of different methods of drying foods for preservation. The most important are sun drying, tunnel or cabinet drying, drum drying, spray drying and freeze drying.

There are number of different methods of drying foods for preservation. The most important are sun drying, tunnel or cabinet drying, drum drying, spray drying and freeze drying.Foods to be dried must be washed, and some peeled and cut. Others may be pre cooked. Cut fruits are subjected to darkening through enzymes action and must be either blanched or treated with salts or sulfur dioxide. However if treated with sulfur dioxide, the product must be so labeled, because of known allergenic reactions in some consumers. Certain vegetables may be pretreated in the same manner. Sulfuring may also be required to limit non enzymatic browning (the Maillard reactions). Browning refers to the development of brown color.

Various dried eggs products are also subject to browning and also susceptible to the development of off flavors. In this case, the reaction involves a combination of small amount of glucose, which is naturally present, with proteins. Because of this, dried eggs products, especially egg whites, may be treated with glucose oxidase and catalase. The glucose oxidase converts glucose to gluconic acid (which does not combine with amino groups) and hydrogen peroxide. The purpose of the catalase is to convert the undesirable peroxide to water and oxygen. The elimination of glucose may also be done by natural fermentation using microbes. However this process can be considered unsanitary and in order to avoid product spoilage and even food poisoning, it is necessary to hold the product at 130 degree F for several hours after drying.

Various dried eggs products are also subject to browning and also susceptible to the development of off flavors. In this case, the reaction involves a combination of small amount of glucose, which is naturally present, with proteins. Because of this, dried eggs products, especially egg whites, may be treated with glucose oxidase and catalase. The glucose oxidase converts glucose to gluconic acid (which does not combine with amino groups) and hydrogen peroxide. The purpose of the catalase is to convert the undesirable peroxide to water and oxygen. The elimination of glucose may also be done by natural fermentation using microbes. However this process can be considered unsanitary and in order to avoid product spoilage and even food poisoning, it is necessary to hold the product at 130 degree F for several hours after drying.Pretreatment before Process of Drying

Labels:

drying,

method,

preservation,

pretreatment,

process

Tuesday, January 02, 2007

The Effect of drying on microorganisms

The Effect of drying on microorganisms

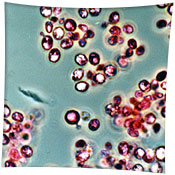

The main purpose of drying foods is to lower their moisture content to a particular level that will exclude the growth of microorganisms (bacteria, mould and yeasts).

For any given moisture content, one food may support the growth of microorganisms will growth in a dried food depends on the water activity.

The lower the water activity of a food, the less probable that microorganisms will grow. Generally, mold at lower water activities than yeasts and yeasts will grow at lower water activities than bacteria. For this reason, mold are opt to grow in dried foods than are yeasts or bacteria.

In dried foods, the moisture content is lowered to the point which microorganisms will not grow and it is kept that way through packaging, which includes moisture.

Water activity also can be lowered by soluble components, such as sugar or salt.

Thus, certain syrup and salted, partially dried foods (e.g foods) are relatively stable as far as at the growth of microorganisms is concerned , although there may be conditions in which they become subject to the growth of yeasts or molds.

The Effect of drying on microorganisms

Labels:

drying,

factor,

microorganism,

moisture

Subscribe to:

Posts (Atom)

Most Popular Articles

-

Milling is the process of removing the husk and splitting whole lentils to produce edible dal. The effectiveness of this process directly in...

-

Direct heating involves direct contact between the food and the heating medium by steam injection or steam infusion. Steam injection intro...

-

Spray drying instant coffee refer to a type of coffee that has been treated with a spray drying process that remove all the water from the c...

-

Yes, alcohol can indeed be made from dates using a traditional process known in some cultures as Dakhai. This method utilizes the natural s...

-

One of the functions of food additives is to maintain product consistency and also improve mouth-feel. Such as emulsifiers give products a...