Freeze drying—technically known as lyophilisation, or cryodesiccation is

a dehydration process typically used to preserve a perishable material

or make the material more convenient for transport. A freeze dried fruit

is a dehydrated fruit derived from lyophilisation which can be stored

for longer duration and can be consumed throughout the year.

Process of freeze drying is practically done in three main phases:

• Freezing, or sub-cooling of product below its eutectic point (cca. -30°C and lower);

• Dehydration (drying) by ice sublimation under vacuum; and

• Completion of product drying up to moisture content lower than 3% by the normal

vacuum drying.

Traditionally, freeze-drying is performed at vacuum (vacuum

freeze-drying, VFD), resulting in extensive drying periods with high

operating costs. In order to shorten this period, alternative processes

can be used, such as atmospheric freeze-drying (AFD), where the primary

drying stage (sublimation) occurs at atmospheric pressure. AFD has been

used successfully for drying of berries. Traditional freeze drying

(lyophilisation) is used to quick freeze and vacuum moisture from

a blueberry. This gets the blueberry to a 2 % moisture level where it

is crunchy.

The freeze dry blueberry maintains all of the nutrients of the blueberry

minus the water and an intense blueberry flavor.

According to one study, freeze drying resulted in a higher retention of

total polyphenols and anthocyanins as well as higher antioxidant

activity in the glycoside forms. (International Journal of Food Engineering, Volume 4, Issue 6 July 2008)

Freeze dried blueberries

Just another blog about food processing and the important of food processing. It is about the conversion of raw materials or ingredients into the consumer product. Food processing also can be defined as the branch of manufacturing that starts with raw animal, vegetable, or marine materials and transforms them into intermediate foods stuff or edible products through the application of labor, machinery, energy, and scientific knowledge.

Showing posts with label preservation. Show all posts

Showing posts with label preservation. Show all posts

Sunday, September 08, 2019

Tuesday, September 12, 2017

What are the main objectives of food processing?

The composition and moisture content of food creates an ideal environment for the growth and proliferation of pathogenic and spoilage microorganisms.

Processing operations involves not just involves just a minor change of form, from dirty to clean but it also involves processing to assure safety, to drastically alter the form of the raw materials, and to provide a product that will remain stable for many months on the shelf.

It must be acknowledge that most if not all food processing operations will influence the physical and sensory characteristics of the product.

Modern food processing preserves food quality, controls food spoilage and disease causing microorganisms, preserves desirable sensory qualities such as flavor, odor, texture, and appearance, preserves nutrients content and in many cases enhances the nutrient value as well.

Processing to retard spoilage permits foods to be consumed at a later date and frequently at a distance from the point of production.

What are the main objectives of food processing?

Processing operations involves not just involves just a minor change of form, from dirty to clean but it also involves processing to assure safety, to drastically alter the form of the raw materials, and to provide a product that will remain stable for many months on the shelf.

It must be acknowledge that most if not all food processing operations will influence the physical and sensory characteristics of the product.

Modern food processing preserves food quality, controls food spoilage and disease causing microorganisms, preserves desirable sensory qualities such as flavor, odor, texture, and appearance, preserves nutrients content and in many cases enhances the nutrient value as well.

Processing to retard spoilage permits foods to be consumed at a later date and frequently at a distance from the point of production.

What are the main objectives of food processing?

Labels:

Food processing,

objective,

operation,

preservation

Friday, October 23, 2015

Process of preservation by removal of water

Removal of water and the consequent lowering of water activity constitutes an important principle of food preservations. The removal of water is usually done by drying dehydration, or evaporation.

Although the term are sometimes interchangeably, drying normally refer to the sun drying, or air drying, evaporation refers to drying by the application of artificial heat but under natural draft, and dehydration implies drying by controlling application of application heat with mechanical circulation of air or under a vacuum.

Drying of food involves complete removal of water under controlled conditions in such a way that the food is not altered and results in minimum changes by the drying process. Dried foods contain moisture to the extend of 1-5 per cent and they have storage stability at room temperature of a year or longer.

The term dehydration refers generally to artificial drying under control conditions. However, in modern food processing the term does not refer to all processes that remove water from foods.

Evaporation is the removal by vaporization of part of the solvent form a solution or dispersion of essentially non-volatile solutes. Evaporation is distinguished from crystallization and drying by the fact that the final product is a concentrated dispersion or solution rather than precipitate solids.

Process of preservation by removal of water

Although the term are sometimes interchangeably, drying normally refer to the sun drying, or air drying, evaporation refers to drying by the application of artificial heat but under natural draft, and dehydration implies drying by controlling application of application heat with mechanical circulation of air or under a vacuum.

Drying of food involves complete removal of water under controlled conditions in such a way that the food is not altered and results in minimum changes by the drying process. Dried foods contain moisture to the extend of 1-5 per cent and they have storage stability at room temperature of a year or longer.

The term dehydration refers generally to artificial drying under control conditions. However, in modern food processing the term does not refer to all processes that remove water from foods.

Evaporation is the removal by vaporization of part of the solvent form a solution or dispersion of essentially non-volatile solutes. Evaporation is distinguished from crystallization and drying by the fact that the final product is a concentrated dispersion or solution rather than precipitate solids.

Process of preservation by removal of water

Labels:

dehydration,

drying,

evaporation,

method,

preservation

Sunday, March 04, 2012

Ancient Times Food Preservation

Food preservation is as old as human civilization. Preservation of foods inhibits spoilage cause by bacterial growth, oxidation, insects or desiccation.

Early humans, probably by trial and error, also started to develop basic forms of food preservation, which possible also made safer, e.g. drying, salting, fermentation.

The Chinese reportedly preserved vegetables by fermentation in prehistoric times and Plinius preserved white cabbage in earthenware pots in Italy in the first century AD.

The earliest recorded instances of food preservation date back to ancient Egypt and the drying of grains and subsequent storage in seal silos.

The stored grain could be kept for several years to insure against famine in case the Nile River flooded.

Fermentation, oil packing, pickling, salting, and smoking are all ancient preservation technologies.

Refrigeration in caves or under cool water were also well known ancient techniques of food preservation.

People in many parts of the world developed techniques for drying and smoking foods as far as 6000 BC. Microorganism need water to carry out their metabolic processes.

Salting was so important in Roman life that Roman soldiers received “salarium,” or salt, as payment. This is the origin of today’s term, ‘salary.’

Ancient Mesoamericans used salt as a preservative for trade in fish and other food stuff over long distances, as well as for storing food for long periods of time.

Since Phoenician times (from around 1250 BC) the standard practice for preserving fish was to gut it, dry it and pack it in layers with salt.

Ancient Times Food Preservation

Early humans, probably by trial and error, also started to develop basic forms of food preservation, which possible also made safer, e.g. drying, salting, fermentation.

The Chinese reportedly preserved vegetables by fermentation in prehistoric times and Plinius preserved white cabbage in earthenware pots in Italy in the first century AD.

The earliest recorded instances of food preservation date back to ancient Egypt and the drying of grains and subsequent storage in seal silos.

The stored grain could be kept for several years to insure against famine in case the Nile River flooded.

Fermentation, oil packing, pickling, salting, and smoking are all ancient preservation technologies.

Refrigeration in caves or under cool water were also well known ancient techniques of food preservation.

People in many parts of the world developed techniques for drying and smoking foods as far as 6000 BC. Microorganism need water to carry out their metabolic processes.

Salting was so important in Roman life that Roman soldiers received “salarium,” or salt, as payment. This is the origin of today’s term, ‘salary.’

Ancient Mesoamericans used salt as a preservative for trade in fish and other food stuff over long distances, as well as for storing food for long periods of time.

Since Phoenician times (from around 1250 BC) the standard practice for preserving fish was to gut it, dry it and pack it in layers with salt.

Ancient Times Food Preservation

Labels:

ancient,

preservation

Wednesday, October 19, 2011

High Pressure Processing

The primary aim of treating foods with high pressure processing in most cases is to reduce or eliminate the relevant foodborne microorganisms that may be present.

Applying high pressure uniformly throughout a food product is another method of non-thermal food preservation. This inactivates microorganisms, spores and undesirable enzymes, and increase the shelf-life of foods without the used of chemical preservatives.

The pH and water activity of foods can also significantly affect the inactivation of microorganism by high pressure processing.

Japanese is a leader in this technology. In Japan, the technique has been used since 1990 on some juice, jams and jellies.

Although it was discovered in 1899, treating foods with high pressure is a relatively mew method of preservation and one still under development.

High pressure processing or pascalization is named after Blaise Pascal, a 17th century French scientist who describe how contained fluids are affected by pressure.

Jams made by high pressure processing retain the taste and color of fresh fruit, unlike conventional cooked jams. High pressure processing is also used in yoghurts, salad dressings and citrus juices.

The draw back of this method it is costly to implement, but interest in the technique was revived during the 1980s and 1990s.

In recent years, food preservation strategies have been developed that combine high pressure processing with the use of anti-microbial food additives.

High Pressure Processing

Applying high pressure uniformly throughout a food product is another method of non-thermal food preservation. This inactivates microorganisms, spores and undesirable enzymes, and increase the shelf-life of foods without the used of chemical preservatives.

The pH and water activity of foods can also significantly affect the inactivation of microorganism by high pressure processing.

Japanese is a leader in this technology. In Japan, the technique has been used since 1990 on some juice, jams and jellies.

Although it was discovered in 1899, treating foods with high pressure is a relatively mew method of preservation and one still under development.

High pressure processing or pascalization is named after Blaise Pascal, a 17th century French scientist who describe how contained fluids are affected by pressure.

Jams made by high pressure processing retain the taste and color of fresh fruit, unlike conventional cooked jams. High pressure processing is also used in yoghurts, salad dressings and citrus juices.

The draw back of this method it is costly to implement, but interest in the technique was revived during the 1980s and 1990s.

In recent years, food preservation strategies have been developed that combine high pressure processing with the use of anti-microbial food additives.

High Pressure Processing

Labels:

high pressure,

pascalization,

preservation

Friday, September 30, 2011

Preservation of fresh juice

Refreshing juices of pleasing flavor can be made from many fruits. The problem is one of to preserving the juice that as much as possible of its fresh flavor and appearance is retained.

Despite the many path ways to deterioration, there are a number of effective preservation methods that have evolved to combat spoilage.

A principle tenant of juice preservation is to maintain the quality and nutritional attributes while preventing spoilage.

Fresh juice can be stored and not lose too many nutrients by keeping it cold, such in an insulated container, covered in the refrigerator. Attention to good sanitation practices from production through juice preparation and low temperature holding are the two processes that capable of extending storage.

Low temperature during manufacture and storage is an valuable hurdle to deterioration, Single strength juice freezing and storage in a low oxygen environment can maintain fresh character as well or better than any other process.

The most practical way of accomplished this is by pasteurization by heat at temperatures from 150 ° to 180 ° F.

Preservation of fresh juice

Despite the many path ways to deterioration, there are a number of effective preservation methods that have evolved to combat spoilage.

A principle tenant of juice preservation is to maintain the quality and nutritional attributes while preventing spoilage.

Fresh juice can be stored and not lose too many nutrients by keeping it cold, such in an insulated container, covered in the refrigerator. Attention to good sanitation practices from production through juice preparation and low temperature holding are the two processes that capable of extending storage.

Low temperature during manufacture and storage is an valuable hurdle to deterioration, Single strength juice freezing and storage in a low oxygen environment can maintain fresh character as well or better than any other process.

The most practical way of accomplished this is by pasteurization by heat at temperatures from 150 ° to 180 ° F.

Preservation of fresh juice

Labels:

juice,

preservation

Friday, September 03, 2010

Preservation of Foods by Heat: The History

Preservation of Foods by Heat: The History

Preservation of foods by heat may be considered as the first invented of preservation technology.

The origins of drying and chemical preservation by alcohol or acid (generated by fermentation) have been lost in history as is the use of ice.

Nicholas Appert, in the late 1700s, applied heat to acid and low acid foods sealed in bottles and eventually received a prize of 12,000 French francs from the French government or inventing a method for safety preserving foods for long term storage.

Appert established a food preservation business in 1812. Peter Durand in England, in the early 1800s, adopted Appert’s process to foods packed in tin coated steel canisters.

While the canisters were hand make, heating of foods in hermetically sealed, tinned steel containers, formed the basis for the first true manufacturing of acid and low acid convenience food products.

The tin can made heat preservation practical as metal containers were more compatible with package filling, sealing, heat processing and the subsequent rigors of storage and distribution.

Early heat preservation technology was constrained by the misconception that air caused food spoilage and by the lack of safe, reliable and properly instrumented steam pressure retorts.

Appert attributes his success at preserving foods by heat to the excellent packaging he developed using glass bottles of his own specification and his carefully prepared stoppers made from hand-cut and glued cork.

He assumed that air was responsible for the spoilage of food. His meticulous procedures for filling and sealing his glass bottles reflect this belief.

Appert was limited to boiling water baths for preservation and heating times were in the order of hours for some products.

Appert’s successor, his son, Raymond Chevallier Appert, adapted the steam autoclave so that packaged foods could be heated above 100 degree C.

The higher temperature allowed shorter heat treatment. Raymond Chevallier Appert could be considered among the first food engineers as he invented a manometer which allowed him to control steam pressure to provide temperatures accurate to 1 degree C.

Preservation of Foods by Heat: The History

Preservation of foods by heat may be considered as the first invented of preservation technology.

The origins of drying and chemical preservation by alcohol or acid (generated by fermentation) have been lost in history as is the use of ice.

Nicholas Appert, in the late 1700s, applied heat to acid and low acid foods sealed in bottles and eventually received a prize of 12,000 French francs from the French government or inventing a method for safety preserving foods for long term storage.

Appert established a food preservation business in 1812. Peter Durand in England, in the early 1800s, adopted Appert’s process to foods packed in tin coated steel canisters.

While the canisters were hand make, heating of foods in hermetically sealed, tinned steel containers, formed the basis for the first true manufacturing of acid and low acid convenience food products.

The tin can made heat preservation practical as metal containers were more compatible with package filling, sealing, heat processing and the subsequent rigors of storage and distribution.

Early heat preservation technology was constrained by the misconception that air caused food spoilage and by the lack of safe, reliable and properly instrumented steam pressure retorts.

Appert attributes his success at preserving foods by heat to the excellent packaging he developed using glass bottles of his own specification and his carefully prepared stoppers made from hand-cut and glued cork.

He assumed that air was responsible for the spoilage of food. His meticulous procedures for filling and sealing his glass bottles reflect this belief.

Appert was limited to boiling water baths for preservation and heating times were in the order of hours for some products.

Appert’s successor, his son, Raymond Chevallier Appert, adapted the steam autoclave so that packaged foods could be heated above 100 degree C.

The higher temperature allowed shorter heat treatment. Raymond Chevallier Appert could be considered among the first food engineers as he invented a manometer which allowed him to control steam pressure to provide temperatures accurate to 1 degree C.

Preservation of Foods by Heat: The History

Labels:

heating,

preservation

Saturday, February 27, 2010

Food Preservation

Food Preservation

There are many techniques used to preserve food such as legal food additives, varying levels of food ingredients or components, and new technology.

Legal food additives, among other functions, can prevent oxidation and inhibit or destroy harmful microorganisms.

Vitamin E or vitamin C can serve as an antioxidant in many food products, and benzoate in beverages can act as an anti-microbial agent.

We can preserve food by manipulating the levels of food ingredients or components to inhibit the growth of microorganisms or destroy them.

For example, keep the food low in moisture content (low water activity), high in sugar or salt content, or at a low pH (less than pH 5).

Food Preservation

There are many techniques used to preserve food such as legal food additives, varying levels of food ingredients or components, and new technology.

Legal food additives, among other functions, can prevent oxidation and inhibit or destroy harmful microorganisms.

Vitamin E or vitamin C can serve as an antioxidant in many food products, and benzoate in beverages can act as an anti-microbial agent.

We can preserve food by manipulating the levels of food ingredients or components to inhibit the growth of microorganisms or destroy them.

For example, keep the food low in moisture content (low water activity), high in sugar or salt content, or at a low pH (less than pH 5).

Food Preservation

Labels:

preservation

Monday, July 13, 2009

Use of High Temperatures for Food Preservation

Use of High Temperatures for Food Preservation

Preservation of food by the use of heat finds very wide applications compared to other methods.

Heat may be used either for processing or conversion of foods or simply as a means or preserving the food.

In heat processing or conversion the application of heat is used primarily to effect chemical changes in food.

Cooking, frying and baking involve both processing and preservation operations.

Cooking makes food palatable and tender and also destroys a large proportion of microorganisms and natural enzymes.

Cooked foods can be stored for several days provided they are protected from recontamination.

Refrigeration cooked food is a normal household practice to prolong the storage time.

However, cooking will not sterilize a product.

Cooking also destroys the toxin formed by Clostridium botulinum during a ten minute exposure of the food to moist heat at 100 degree C.

Thus cooking provides a final measure of protection for consumer form food borne diseases.

The killing of microorganisms by heat is due to thermal denaturation of protein and enzymes of the microorganism required for its metabolic activity and growth.

The heat treatment necessary to kill the organisms or spores varies with the kind of organism, its state and the environment during heating.

The type of heat treatment will depend on the kind of organism to be killed, other preservative methods to be employed and the effect of heat on the food.

The use of heat also affects the food adversely and hence it is necessary to use only mild heat treatment that ensures freedom from pathogens and enzyme activity and enhance the self life of the food.

Use of High Temperatures for Food Preservation

Preservation of food by the use of heat finds very wide applications compared to other methods.

Heat may be used either for processing or conversion of foods or simply as a means or preserving the food.

In heat processing or conversion the application of heat is used primarily to effect chemical changes in food.

Cooking, frying and baking involve both processing and preservation operations.

Cooking makes food palatable and tender and also destroys a large proportion of microorganisms and natural enzymes.

Cooked foods can be stored for several days provided they are protected from recontamination.

Refrigeration cooked food is a normal household practice to prolong the storage time.

However, cooking will not sterilize a product.

Cooking also destroys the toxin formed by Clostridium botulinum during a ten minute exposure of the food to moist heat at 100 degree C.

Thus cooking provides a final measure of protection for consumer form food borne diseases.

The killing of microorganisms by heat is due to thermal denaturation of protein and enzymes of the microorganism required for its metabolic activity and growth.

The heat treatment necessary to kill the organisms or spores varies with the kind of organism, its state and the environment during heating.

The type of heat treatment will depend on the kind of organism to be killed, other preservative methods to be employed and the effect of heat on the food.

The use of heat also affects the food adversely and hence it is necessary to use only mild heat treatment that ensures freedom from pathogens and enzyme activity and enhance the self life of the food.

Use of High Temperatures for Food Preservation

Labels:

heat,

preservation,

temperature

Saturday, December 27, 2008

Principle of Food Preservation

Principle of Food Preservation

The basic principles of food preservation primary involves the process of inhibiting

In addition, spoilage of food may be caused during mechanical handling, processing, packaging, storing and transportation. Appropriate care has to be exercised to prevent deterioration of quality of food.

Several methods are available for preservation of food based on the above principles, the method include:

Food preservation as it is practiced in the industry always involves the use of combination of methods for achieving maximum effectiveness.

Asepsis or preventing the accessibility of food to microorganisms is well exemplified in nature, the protective covering in natural foods such as skins on fruits and vegetables, shells on eggs and nuts and skins and membranes on livestock and fish prevent the attack by microorganisms and maintain the living tissues in healthy condition.

Microbial attack is facilitated only after the death of the animal or when the skin is physically damaged. Packaging of foods and food products in a variety of materials such as metal cans, plastic films pouches, bags or boxes, paper bags or cartons and glass bottles provide effective protection against microbial attack.

Filtration or centrifugation is adopted to physically remove microorganisms particularly in liquid foods such as milk, soft drinks, fruits juices and alcoholic beverages such as wine and beer.

Principle of Food Preservation

The basic principles of food preservation primary involves the process of inhibiting

- The growth and activity of microorganism

- Activity of endogenous enzymes

- Chemical reactions which may deteriorate the quality of food

- Invasion and spoilage by insects and rodents

In addition, spoilage of food may be caused during mechanical handling, processing, packaging, storing and transportation. Appropriate care has to be exercised to prevent deterioration of quality of food.

Several methods are available for preservation of food based on the above principles, the method include:

- Preventing the accessibility of food to microorganism by asepsis and packaging

- Physical removal of microorganisms from food by filtration or centrifugation

- Hindering the growth and activity of microorganism by use of preservatives, use of low temperatures atmospheric control in packaging and storing of foods and decreasing water activity in foods by drying or evaporation

- Killing the microorganism by use of high temperature and ionizing radiation

- Inactivation of endogenous enzymes by moderate heating

- Inhibition of chemical reaction through the use of chemical additives

- Fermentation of foods to yield more stable or less perishable food product

Food preservation as it is practiced in the industry always involves the use of combination of methods for achieving maximum effectiveness.

Asepsis or preventing the accessibility of food to microorganisms is well exemplified in nature, the protective covering in natural foods such as skins on fruits and vegetables, shells on eggs and nuts and skins and membranes on livestock and fish prevent the attack by microorganisms and maintain the living tissues in healthy condition.

Microbial attack is facilitated only after the death of the animal or when the skin is physically damaged. Packaging of foods and food products in a variety of materials such as metal cans, plastic films pouches, bags or boxes, paper bags or cartons and glass bottles provide effective protection against microbial attack.

Filtration or centrifugation is adopted to physically remove microorganisms particularly in liquid foods such as milk, soft drinks, fruits juices and alcoholic beverages such as wine and beer.

Principle of Food Preservation

Labels:

food,

microorganisms,

preservation,

principle

Tuesday, October 28, 2008

Pretreatment before Process of Drying

Pretreatment before Process of Drying

The preservation of foods by drying is probably the oldest food preservation process practiced by humans. It is believed that many foods, especially grains and fruits of high sugar content, were preserved by primitive peoples by allowing them to dry in the sun. Spices and fish, cut into thin strips, were also preserved in this manner.

There are number of different methods of drying foods for preservation. The most important are sun drying, tunnel or cabinet drying, drum drying, spray drying and freeze drying.

There are number of different methods of drying foods for preservation. The most important are sun drying, tunnel or cabinet drying, drum drying, spray drying and freeze drying.

Foods to be dried must be washed, and some peeled and cut. Others may be pre cooked. Cut fruits are subjected to darkening through enzymes action and must be either blanched or treated with salts or sulfur dioxide. However if treated with sulfur dioxide, the product must be so labeled, because of known allergenic reactions in some consumers. Certain vegetables may be pretreated in the same manner. Sulfuring may also be required to limit non enzymatic browning (the Maillard reactions). Browning refers to the development of brown color.

Various dried eggs products are also subject to browning and also susceptible to the development of off flavors. In this case, the reaction involves a combination of small amount of glucose, which is naturally present, with proteins. Because of this, dried eggs products, especially egg whites, may be treated with glucose oxidase and catalase. The glucose oxidase converts glucose to gluconic acid (which does not combine with amino groups) and hydrogen peroxide. The purpose of the catalase is to convert the undesirable peroxide to water and oxygen. The elimination of glucose may also be done by natural fermentation using microbes. However this process can be considered unsanitary and in order to avoid product spoilage and even food poisoning, it is necessary to hold the product at 130 degree F for several hours after drying.

Various dried eggs products are also subject to browning and also susceptible to the development of off flavors. In this case, the reaction involves a combination of small amount of glucose, which is naturally present, with proteins. Because of this, dried eggs products, especially egg whites, may be treated with glucose oxidase and catalase. The glucose oxidase converts glucose to gluconic acid (which does not combine with amino groups) and hydrogen peroxide. The purpose of the catalase is to convert the undesirable peroxide to water and oxygen. The elimination of glucose may also be done by natural fermentation using microbes. However this process can be considered unsanitary and in order to avoid product spoilage and even food poisoning, it is necessary to hold the product at 130 degree F for several hours after drying.

Pretreatment before Process of Drying

The preservation of foods by drying is probably the oldest food preservation process practiced by humans. It is believed that many foods, especially grains and fruits of high sugar content, were preserved by primitive peoples by allowing them to dry in the sun. Spices and fish, cut into thin strips, were also preserved in this manner.

There are number of different methods of drying foods for preservation. The most important are sun drying, tunnel or cabinet drying, drum drying, spray drying and freeze drying.

There are number of different methods of drying foods for preservation. The most important are sun drying, tunnel or cabinet drying, drum drying, spray drying and freeze drying.Foods to be dried must be washed, and some peeled and cut. Others may be pre cooked. Cut fruits are subjected to darkening through enzymes action and must be either blanched or treated with salts or sulfur dioxide. However if treated with sulfur dioxide, the product must be so labeled, because of known allergenic reactions in some consumers. Certain vegetables may be pretreated in the same manner. Sulfuring may also be required to limit non enzymatic browning (the Maillard reactions). Browning refers to the development of brown color.

Various dried eggs products are also subject to browning and also susceptible to the development of off flavors. In this case, the reaction involves a combination of small amount of glucose, which is naturally present, with proteins. Because of this, dried eggs products, especially egg whites, may be treated with glucose oxidase and catalase. The glucose oxidase converts glucose to gluconic acid (which does not combine with amino groups) and hydrogen peroxide. The purpose of the catalase is to convert the undesirable peroxide to water and oxygen. The elimination of glucose may also be done by natural fermentation using microbes. However this process can be considered unsanitary and in order to avoid product spoilage and even food poisoning, it is necessary to hold the product at 130 degree F for several hours after drying.

Various dried eggs products are also subject to browning and also susceptible to the development of off flavors. In this case, the reaction involves a combination of small amount of glucose, which is naturally present, with proteins. Because of this, dried eggs products, especially egg whites, may be treated with glucose oxidase and catalase. The glucose oxidase converts glucose to gluconic acid (which does not combine with amino groups) and hydrogen peroxide. The purpose of the catalase is to convert the undesirable peroxide to water and oxygen. The elimination of glucose may also be done by natural fermentation using microbes. However this process can be considered unsanitary and in order to avoid product spoilage and even food poisoning, it is necessary to hold the product at 130 degree F for several hours after drying.Pretreatment before Process of Drying

Labels:

drying,

method,

preservation,

pretreatment,

process

Friday, October 10, 2008

Food Preservation by Canning

Food Preservation by Canning

Food Preservation by CanningUsing high temperatures to kill microorganisms in food is one of the principal processes implemented on the preservation of food. The canning industry uses this method most extensively.

Acidity greatly reduces the time and temperature necessary to preserve foods by heat, even though that may contain resistant spores. High acid food such as grapes, pineapples, oranges and tomatoes, for examples, require only a few minutes at 100 degree C to preserve them; foods with acidity, such as spinach, corn, carrots, and beans, require much longer periods at high temperature – depending on the solidity, size of the packages and the amount of preheating.

There are three primary thermal processing methods used today; the conventional retort, the hot-fill and the high temperature short time methods (HTST).

The conventional retort method includes filling the can with the food product, heating the can sufficiently to kill microorganisms, sealing and slowly cooling the can. Whether the slow cooling period damages the food, whether the food is overcooked, and the type of food to be preserved must all be considered when this method is chosen.

The hot fill method is used primarily for high acid foods. Then a comparatively low temperature is sufficient to reduce the microbial; population to an insignificant level due to the pH level of these foods. The food is simply heated near boiling in a method similar to pasteurization poured into a sterile can while hot, and sealed.

Another commonly used method in the heat processing of food is the HTST method. Here the food is poured into the can and exposed to a high temperature for a comparatively brief time. Sealing is accomplished at the maximum temperatures, followed by rapid cooling. This rapid cooling, usually by immersion in cold water, prevents physical damage and over cooking of the product. One major problem with this process is that any microscopic leaks in the can allow the partial vacuum caused by the contraction of cooling to draw any microorganisms in the cooling water into the can.

Food Preservation by Canning

Labels:

canning,

conventional,

cooling,

food,

HTST,

preservation,

processing,

temperature

Saturday, April 21, 2007

Food Preservation by High Osmotic Pressure

Food Preservation by High Osmotic Pressure

Bacteria reach osmotic equilibrium by two means:

1. In hypertonic environments the volume of the protoplasts will shrink, and

2. In hypotonic environments the rigid wall will resist increase in protoplasts volume at a limiting volume of water; equilibriums results from turgor against the wall.

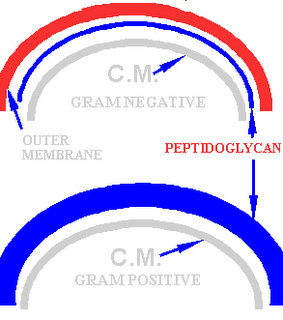

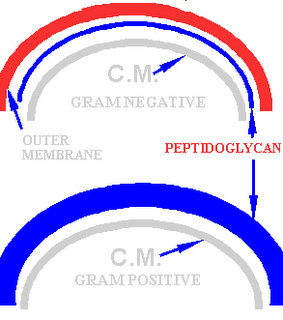

The rigid wall present in bacteria cells enable most bacteria to tolerate even extremely dilute environments. Osmotic equilibrium is achieved by development of turgor pressure against the wall. The wall of gram-positive micrococci can withstand 22 atm of pressure.

Although the walls of gram-negative rods have lower tensile strength, the wall is sufficiently strong to retain the turgor pressure if the cell is suspended in water.

Food Preservation by High Osmotic Pressure

Bacteria reach osmotic equilibrium by two means:

1. In hypertonic environments the volume of the protoplasts will shrink, and

2. In hypotonic environments the rigid wall will resist increase in protoplasts volume at a limiting volume of water; equilibriums results from turgor against the wall.

The rigid wall present in bacteria cells enable most bacteria to tolerate even extremely dilute environments. Osmotic equilibrium is achieved by development of turgor pressure against the wall. The wall of gram-positive micrococci can withstand 22 atm of pressure.

Although the walls of gram-negative rods have lower tensile strength, the wall is sufficiently strong to retain the turgor pressure if the cell is suspended in water.

Food Preservation by High Osmotic Pressure

Labels:

high pressure,

osmotic,

preservation,

process

Sunday, January 28, 2007

Preservation by High Osmotic Pressure

Preservation by High Osmotic Pressure

Bacteria reach osmotic equilibrium by two means:

1.In hypertonic environments the volume of the protoplasts will shrink.

2.In hypotonic environments the rigid wall will resist increase in protoplasts volume at a limiting volume of water; equilibrium results from turgor against the wall.

The rigid wall present in the bacteria cells enables most bacteria to tolerate even extremely dilute environments. Osmotic equilibrium is achieved by the development of turgor pressure against the wall. The wall of gram positive micrococci can withstand 22 atm of pressure.

Although the walls of gram-negative rods have a lower tensile strengths , the walls is sufficiently strong to retain the turgor pressure if the cell is suspended in water.

Although the walls of gram-negative rods have a lower tensile strengths , the walls is sufficiently strong to retain the turgor pressure if the cell is suspended in water.

Turgor against a rigid walls is apparently a much simpler development than the mechanism utilized by many protozoa for similar purposes. Protozoa a contractile vacuole to pump out the water in adapting to osmotic pressure in order to maintain equilibrium.

Preservation by High Osmotic Pressure

Bacteria reach osmotic equilibrium by two means:

1.In hypertonic environments the volume of the protoplasts will shrink.

2.In hypotonic environments the rigid wall will resist increase in protoplasts volume at a limiting volume of water; equilibrium results from turgor against the wall.

The rigid wall present in the bacteria cells enables most bacteria to tolerate even extremely dilute environments. Osmotic equilibrium is achieved by the development of turgor pressure against the wall. The wall of gram positive micrococci can withstand 22 atm of pressure.

Although the walls of gram-negative rods have a lower tensile strengths , the walls is sufficiently strong to retain the turgor pressure if the cell is suspended in water.

Although the walls of gram-negative rods have a lower tensile strengths , the walls is sufficiently strong to retain the turgor pressure if the cell is suspended in water.Turgor against a rigid walls is apparently a much simpler development than the mechanism utilized by many protozoa for similar purposes. Protozoa a contractile vacuole to pump out the water in adapting to osmotic pressure in order to maintain equilibrium.

Preservation by High Osmotic Pressure

Labels:

microorganism,

osmotic,

preservation,

pressure

Subscribe to:

Posts (Atom)

Most Popular Articles

-

Milling is the process of removing the husk and splitting whole lentils to produce edible dal. The effectiveness of this process directly in...

-

Direct heating involves direct contact between the food and the heating medium by steam injection or steam infusion. Steam injection intro...

-

Spray drying instant coffee refer to a type of coffee that has been treated with a spray drying process that remove all the water from the c...

-

Yes, alcohol can indeed be made from dates using a traditional process known in some cultures as Dakhai. This method utilizes the natural s...

-

One of the functions of food additives is to maintain product consistency and also improve mouth-feel. Such as emulsifiers give products a...